The D-Series is punkers newest product family and offers our customers a standardized solution for challenges in the commercial heating, ventilation and air conditioning (HVAC) industry.

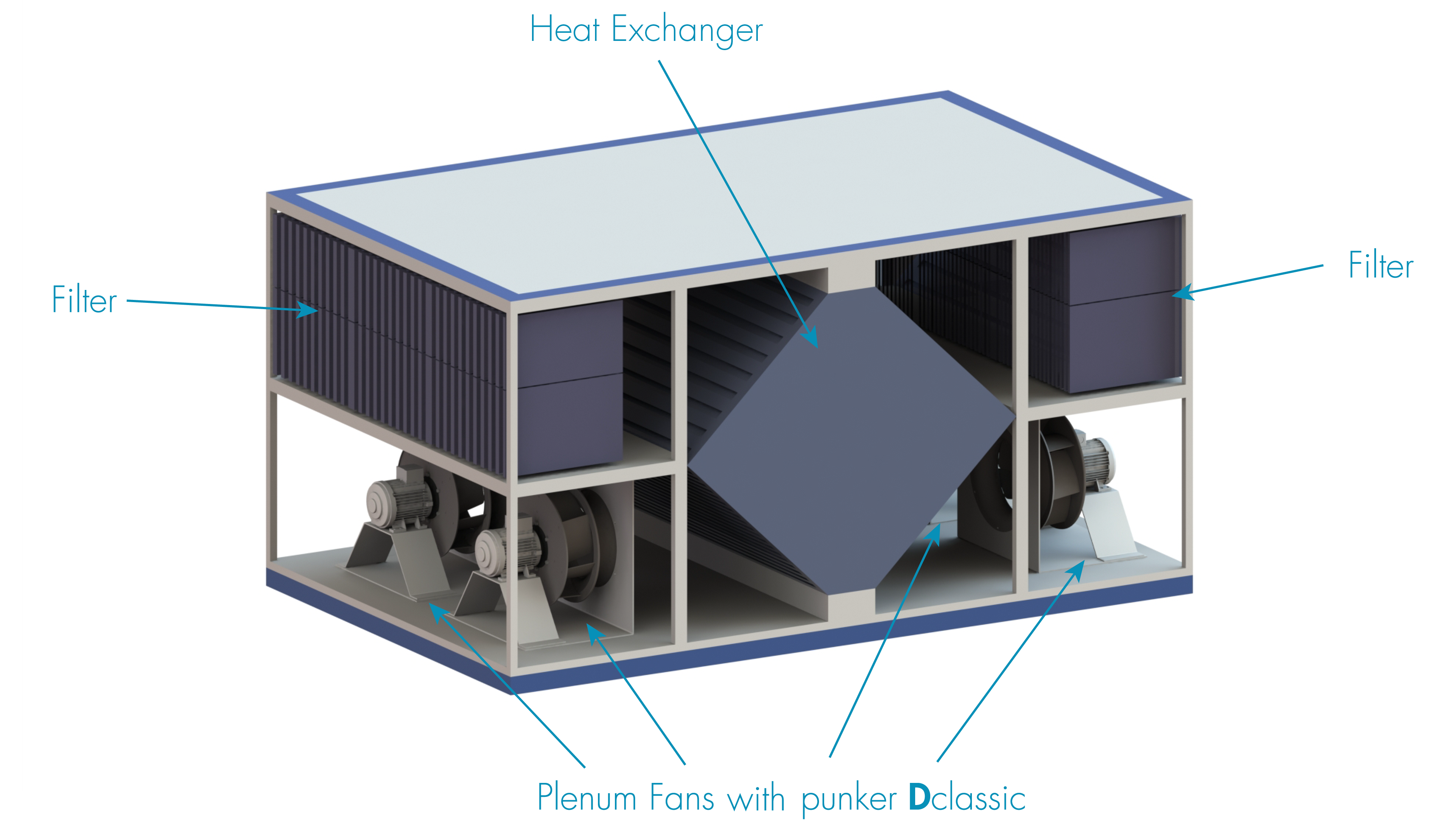

This product family is used in free-blowing applications (i.e. without the use of a spiral housing), mainly in ventilation and air-conditioning systems. The fan draws air through various components such as heat exchangers and air filters and then blows freely into the room or downstream ducts. Free-blowing fans are also called plug or plenum fans. In larger HVAC systems it is quite common for several small fans to be connected and stacked in parallel instead of one large one. This type of construction is called fan wall or fan array. Advantages include easier fan handling and system redundancy (if one fan fails, its performance is compensated by the remaining fans). The following diagram schematically shows the structure of an air handling unit.

The D-Series builds on the technology platform of the R63 diffusor wheel geometry. This platform strategy enables punker to achieve a comparable characteristic curve for different mechanical properties and materials. This enables us to use the Dlight, Dclassic and Dprime wheels to serve different fan segments for large air-conditioning units. If you take a look outside our core markets in Europe, a wheel from the D-Series stands out especially. The Dclassic is today’s star in our export markets. In addition to its success in the USA, Dclassic is developing its potential in Russia, India and the Far East. The secret of the Dclassic‘s success is its all-round characteristic. With regard to the mechanical properties, it lies between Dlight (applicable at peripheral speeds up to 55 m/s) and Dprime (applicable at max. 95 m/s). The solid peripheral speed of up to 75 m/s results in high speed stability across all diameters (225 m to 1000 mm). This in turn is reflected in the static pressure increase up to a maximum of 2500 Pascal. With this pressure increase, approx. 80% of the typical air conditioning systems can be covered both on the supply air and exhaust side. During operation, the Dclassic can be operated either with a direct drive at the mains voltage of the respective country, or it can be variably adapted to the respective operating point by means of a frequency converter. In these markets, fans with EC motors (electrical commutation), common in Europe in external rotor design, are not yet widespread. Our experience shows that traditional AC standard motors are still preferred.

For this application the Dclassic shows its strength and high flexibility. In addition to simple assembly, the Taperlock hub also allows the customer to exchange flexible bushings directly on site, if necessary without any rebalancing. This enables the customer to react flexibly to changing operating requirements. The typical Taperlock bushes are available in all common industrial markets. With a traditional fixed or disc hub, the bore in the hub cannot be adjusted. The wheels are available with only one width per diameter. This allows the number of available variants to be reduced without making technical compromises. Thanks to the flexibility gained, our customer can place efficient sea freight container orders. We can bring requirements together and thus offer our customers more attractive conditions. A win-win situation for both sides.

We were able to convince the following customers of these advantages and implemented Dclassic together successfully:

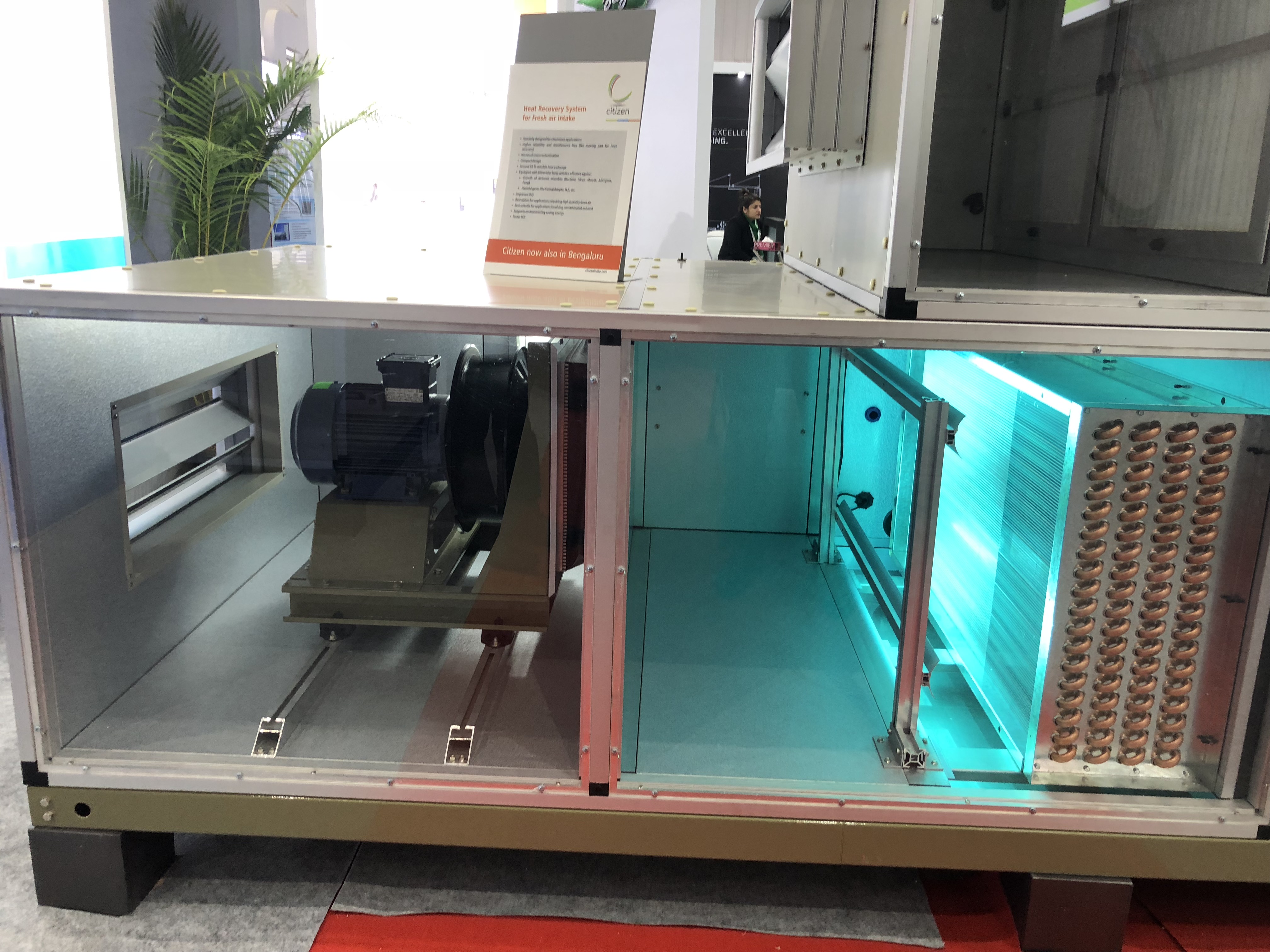

Our long-time customer Citizen relies completely on our Dclassic. Citizen’s equipment is mainly used in the pharmaceutical industry throughout India. In the past, we have supplied various series in a wide variety of diameters, blade widths, coatings and hub variants. Finally, we had countless variants in the system. With our help Citizen standardized their own plenum fan program. With the help of the Dclassic we were able to successfully reduce the large number of variants to the respective Dclassic diameters. Further details can be found in our Citizen Case Study.

The company Artex is our representative in Korea. We have specialized in the sale of our Dclassic to local fan manufacturers and project offices. Artex customers complete their Plenum Fans and integrate these products into their projects, e.g. for the construction of new air handling units or the modernisation of existing systems in the field. The latter is referred to as retrofit applications. Due to the wide range of customers that Artex serves from a single source, the flexibility of the Dclassic is indispensable.

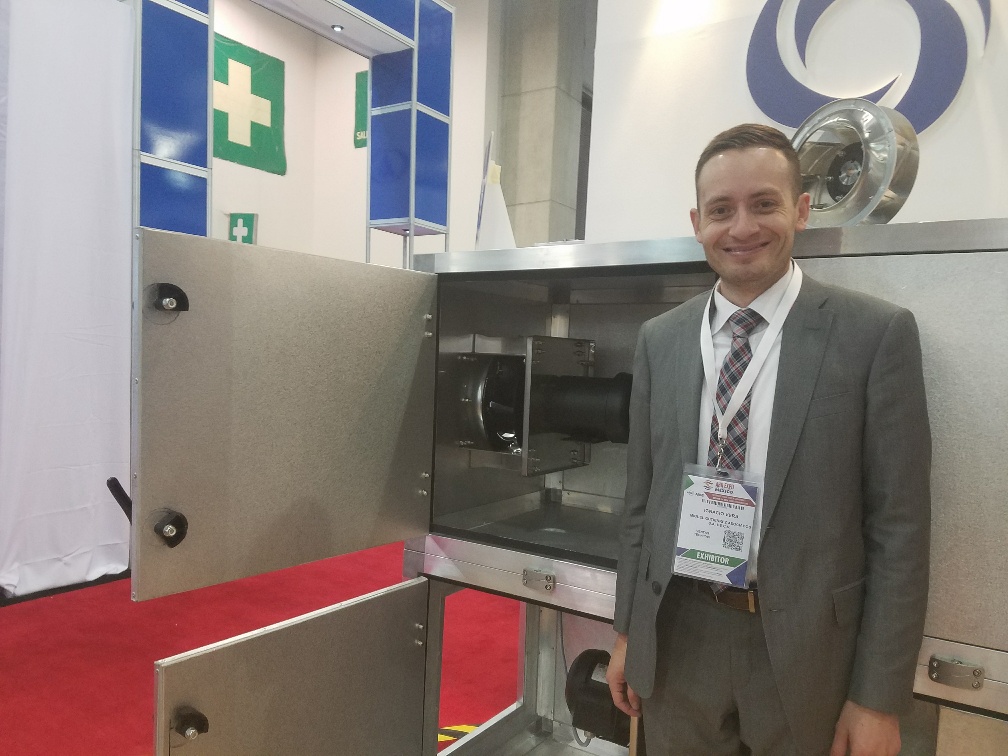

Harfko Fair with Artex – left Eugene Jang, Joshua Shin, Stanislav Markitan and David Kim – right the punker D-Series

Harfko Fair with Artex – left Eugene Jang, Joshua Shin, Stanislav Markitan and David Kim – right the punker D-Series

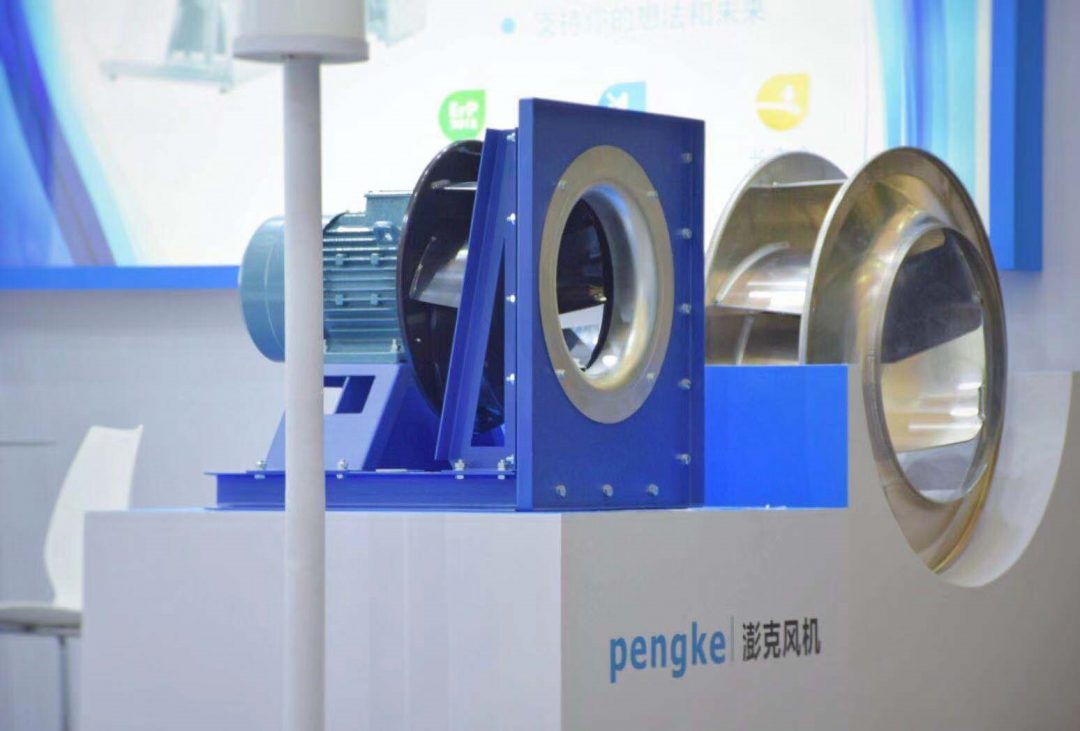

The company pengke is our administration partner for logistic topics in China, furthermore pengke sells plenum fans with our Dclassic for modernization projects of old air handling units all over China. Also for pengke the all-rounder characteristic is the key to success.

The success story of the Dclassic has sustainably strengthened our market position in India and the Far East. Every day we work on serving the wishes of our existing customers and new potentials more efficiently. I look confidently into the future and look forward to reporting more stories soon.

The exposition took place in the Las Vegas Convention Center (Jan. 30 to Feb. 1, 2017). Honestly, we had some doubts if Las Vegas was the right place for an industry trade show. But only 30 minutes after the opening these doubts proved wrong: The enormous appeal of ‘fabulous Las Vegas’ brought a visitors record already on day one. Obviously, many visitors combined a visit of Las Vegas and the trade show by arriving already the weekend before.

The exposition took place in the Las Vegas Convention Center (Jan. 30 to Feb. 1, 2017). Honestly, we had some doubts if Las Vegas was the right place for an industry trade show. But only 30 minutes after the opening these doubts proved wrong: The enormous appeal of ‘fabulous Las Vegas’ brought a visitors record already on day one. Obviously, many visitors combined a visit of Las Vegas and the trade show by arriving already the weekend before.