In my blog post “ENERGY EFFICIENCY- THE HVAC-INDUSTRY IS ENTERING NEW TERRITORY” from October 2015, I talked about developments regarding energy efficiency in the USA.

In December 2015, the U.S. Department of Energy (DOE) finalized new energy conservation standards for commercial air conditioners, heat pumps and commercial warm-air furnaces.

According to Ernest Moniz, U.S. Energy Secretary, this “marks the largest energy saving standard in history and demonstrates that America is leading the effort to reduce energy costs and cut carbon emissions.”

The DOE estimates the new program will save businesses up to $167 billion in energy costs over the lifetime of the equipment. Additionally, carbon monoxide discharge will be reduced by as much as 885 million metric tons over a period of thirty years.

The new directive was finalized with cooperation between the DOE and 17 stakeholder groups including industry organization, manufacturers, efficiency organizations and institutes. The new standard will be implemented in two phases:

- Beginning January 1, 2018 commercial air conditioners and commercial warm air furnaces must achieve thirteen percent improvement in efficiency.

- In 2023, an additional fifteen percent increase will be required.

How can punker help manufacturers of commercial air conditioning systems?

The DOE’s final ruling delivers a clear regulatory roadmap to manufacturers of commercial air conditioning systems. This will force manufacturers to rise to the challenge of optimizing their products accordingly.

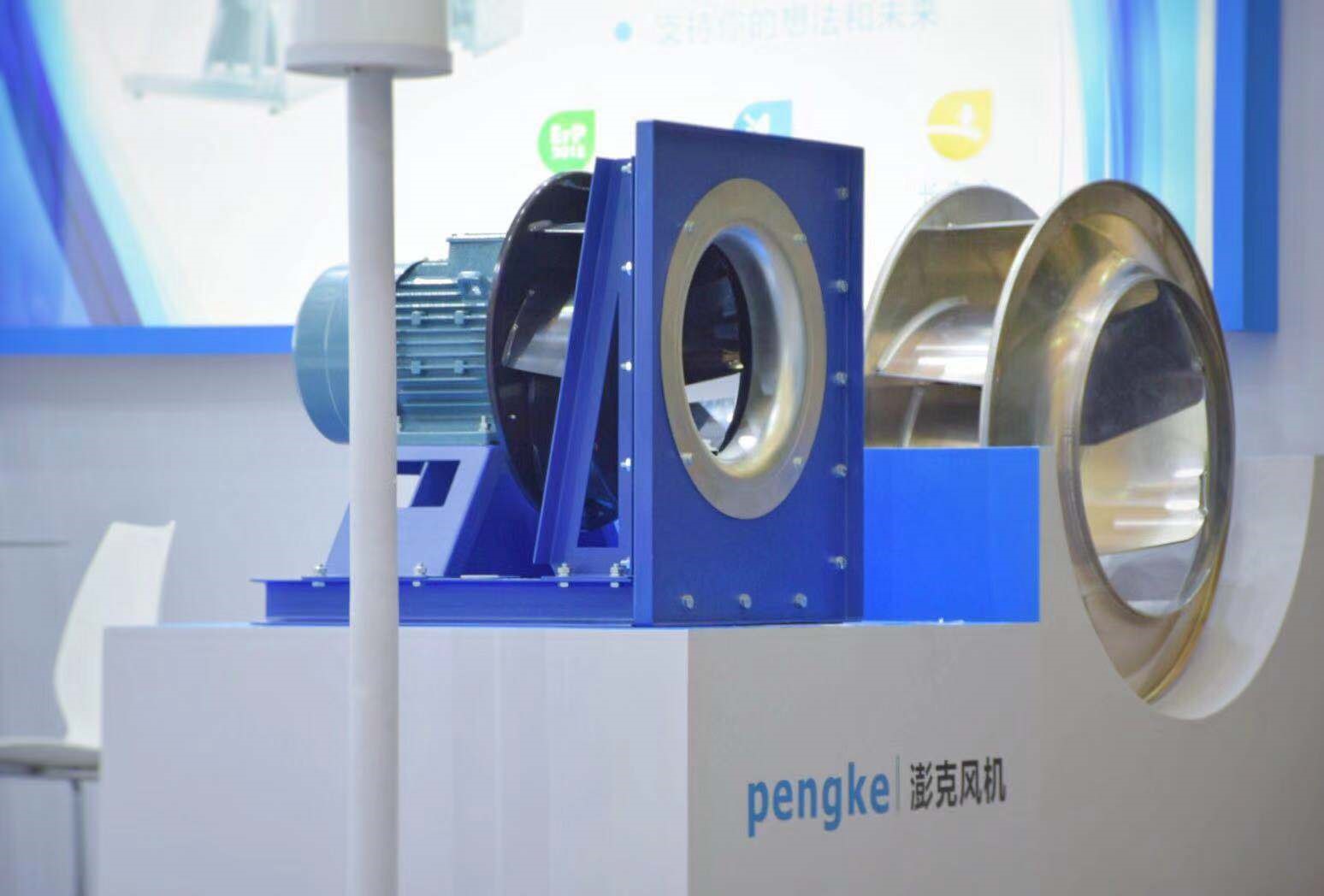

As a leading developer and manufacturer of radial fan wheels, punker has been focusing its product development on energy efficiency since the European Union’s Eco-design Directive “ErP” (Energy related Products) extended its scope to air conditioning and ventilation systems in a 2009 revision.

The ErP defines minimum efficiency requirements for fans with an output range of 0.125 kw to 500 kw and took effect in two phases in 2013 and 2015. The assessment takes into account the efficiency of the entire systems, consisting of the motor, the transmission (belt drive, for example) and the fan wheel.

The fan wheel has a large impact on the overall efficiency of the fan system. This is where manufacturers of unhoused fan applications can rely on punker’s extensive knowledge and expertise. Our product portfolio offers suitable fan wheels for plug fans and plenum fans to meet the DOE’s new efficiency requirements. Our fan wheel series R63D HVAC and D light, are constructed to achieve the highest static efficiencies at optimal working points worldwide.

Here at punker, we look forward to assisting manufacturers in turning these challenges into opportunities.

No Comments